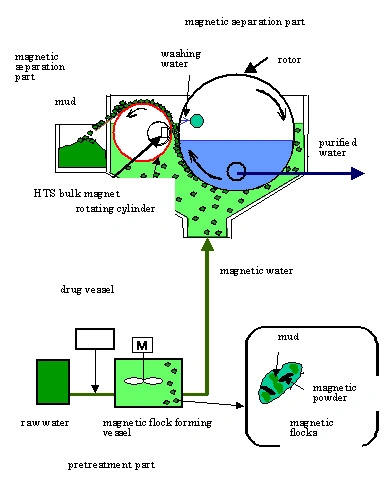

Wet Magnetic separator working principle :

The pulp flows into cell body from the pulp box, and under the water flow of the feeding spray pipe, the mineral grain will go into the feeding area of the cell body in the loose condition. In the magnetic field, the magnetic ore particles will have magnetic gathering and form magnet group or magnet chain which is influenced by the magnetic force inside the pulp and moves to the magnetic pole and finally is absorbed onto the cylinder.

Since the polarity of the magnetic pole along the rotary direction of the cylinder is alternately arranged and is fixed during the working process, when the magnet group or magnet chain rotate with the cylinder, it will have magnetic mixing due to the alternation of the polarity, as a result of which, the non magnetic ore such as gangue mixed up with the magnet group or magnet chain will split away off in the stirring, and the magnet group or magnet chain that is finally absorbed onto the surface of the cylinder is concentrate. The concentrate rotates to the edge of the magnetic system where the magnetic force is the weakest along with the cylinder, and under the water flow of the discharging spray pipe, it will be discharged to the concentrate chute. If the roller is all magnetic roller, the ore discharging is completed by brush roll. The non magnetic and weak magnetic minerals are kept in the pump and are discharged from the chute with the pulp to become tailing.

Advantages of wet magnetic separator

1) Short magnetic circuit

2) little magnetic flux leakage

3) high magnetic intensity

4) low energy consumption

5) fine beneficiating results

6) simple structure and easy to maintain

Wet magnetic separator main technical parameters:

| Model | Magnetic field strength (oe) | Capacity (t/h) | Power (kw) | Weight (kg) |

| CTB600X900 | 1450 | 8-15 | 1.1 | 910 |

| CTB600X1800 | 1500 | 15-25 | 2.2 | 1340 |

| CTB750X1800 | 1550 | 30-45 | 3 | 2050 |

| CTB900X1800 | 1650 | 35-60 | 4 | 3000 |

| CTB1050X2400 | 1650 | 60-95 | 5.5 | 5020 |

| CTB1200X3000 | 1650 | 80-150 | 7.5 | 7800 |

| CTB1500X3000 | 1650 | 120-200 | 11 | 9600 |

1.How is the quality of your product?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2.Guaranteed:

If product quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about Price?

We are manufacturer of 20 years experiences, and be able to give you the lowest price than market one, and we have a policy that " for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity".

Contact us :

Sara

Mobile phone : 0086 137 8347 1727